Production

Everything starts by choosing 0.5 mm thin sheets of wood, which are selected depending on their mechanical and aesthetic characteristics.

The seven sheets of wood alternate with the two layers of aluminum. Inserting the fibers longitudinally and transversely, the frame becomes flexible and resistant.

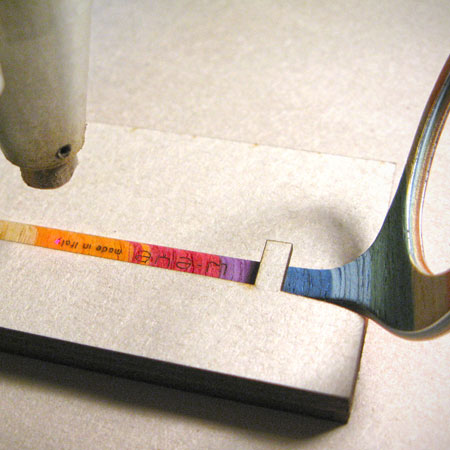

After the gluing phase, the blank stays under the press for 40 minutes. After that a CNC milling machine cuts the shape on the basis of a digital design.

Finally the smoothing and rounding are performed by hand with care and passion. Furthermore the frame is checked and tested on its resistance, elasticity, quality and finish.

The painting is the last step and serves to protect the wood from premature aging.

Unique and Bespoke

It’s easy to use words such as “unique”, “bespoke”, “handmade”, losing the real meaning of these descriptions.

Each and every W-Eye® is checked by hand, simply because only with hands and eyes you can feel its tactile quality and unique beauty.

Thanks to their elasticity and lightness, W-Eye® frames respect the uniqueness of every face and glance, being adjustable to every facial feature.

The absence of hinges is above all a technical solution which helps, through a more equal weight distribution, to create a comfortable and pleasant feeling, giving life to an object which you cannot live without.

Every W-Eye® frame is customizable.

Furthermore it is possible to choose between different sizes for the frame and the bridge. After completion the frame is branded with a sophisticated laser system, engraving the traceability of the glasses and, upon request, customization.

In this way, each pair of glasses remains a unique piece.